REEF TO RIDGE RESTORATION CENTER | HAWAII, USA

-

![]()

Pre-construction site of Arizona State University’s Ridge to Reef Restoration Center (3RC) at the Hawaii Ocean Science & Technology Park, Kailua-Kona, Hawaii.

-

![]()

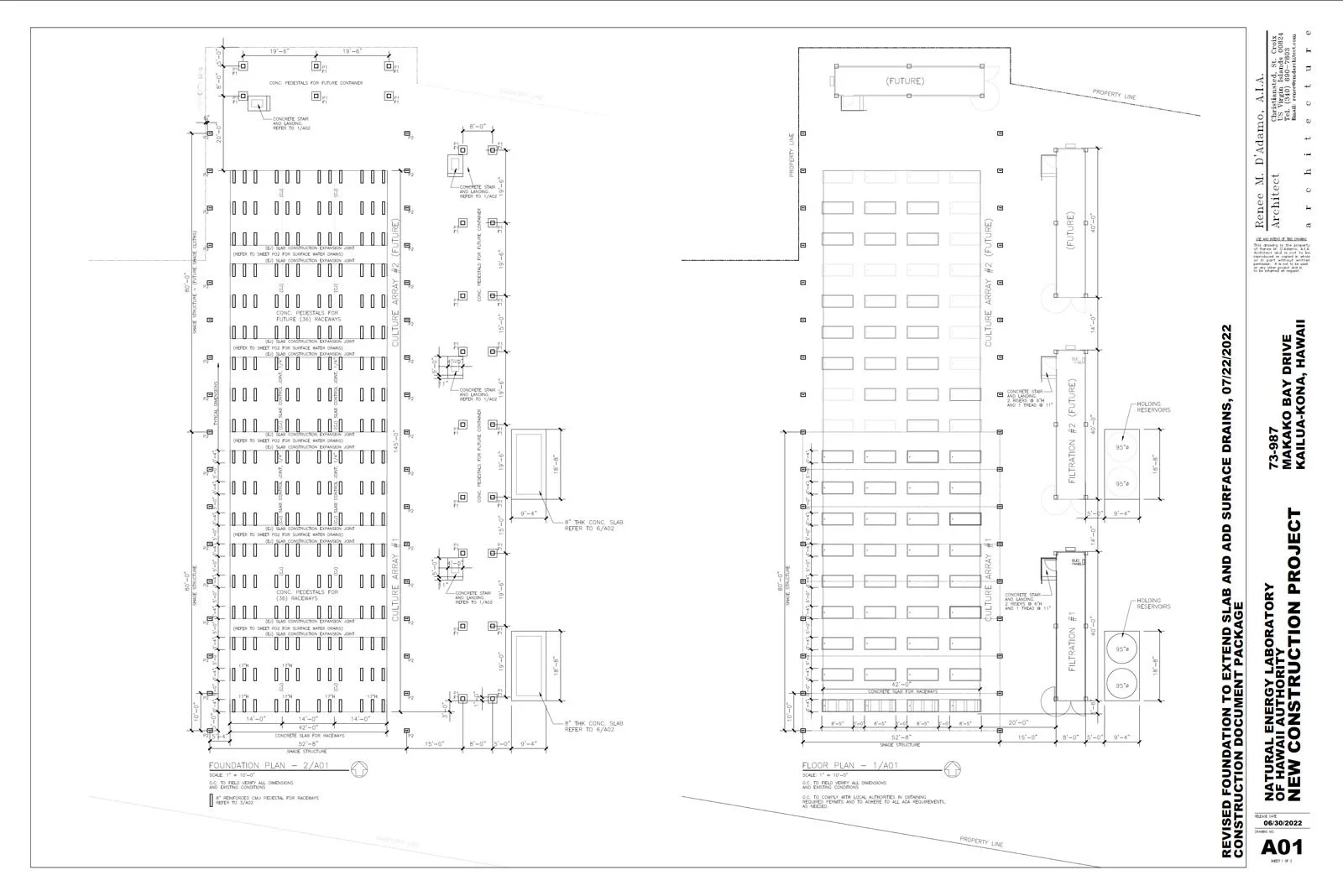

CEE designs and provides architectural blueprints of the facility.

-

![]()

At the client’s request, CEE produced a set of architectural renderings prior to construction.

-

![]()

Two 40’ high-cube shipping containers are fabricated into Life Suport Systems for the facility.

-

![]()

Door and structural supports for equipment and components are welded into the containers.

-

![]()

Industrial-grade coatings are applied to the interiors of the containers.

-

![]()

Hot rolled Polyaspartic floor coating.

-

![]()

Container modifications for electrical and equipment installations begin.

-

![]()

Filtration equipment pre-assembly and intial layout.

-

![]()

Staging of plumbing valves, fittings, bulkheads, and components for pre-fabrication.

-

![]()

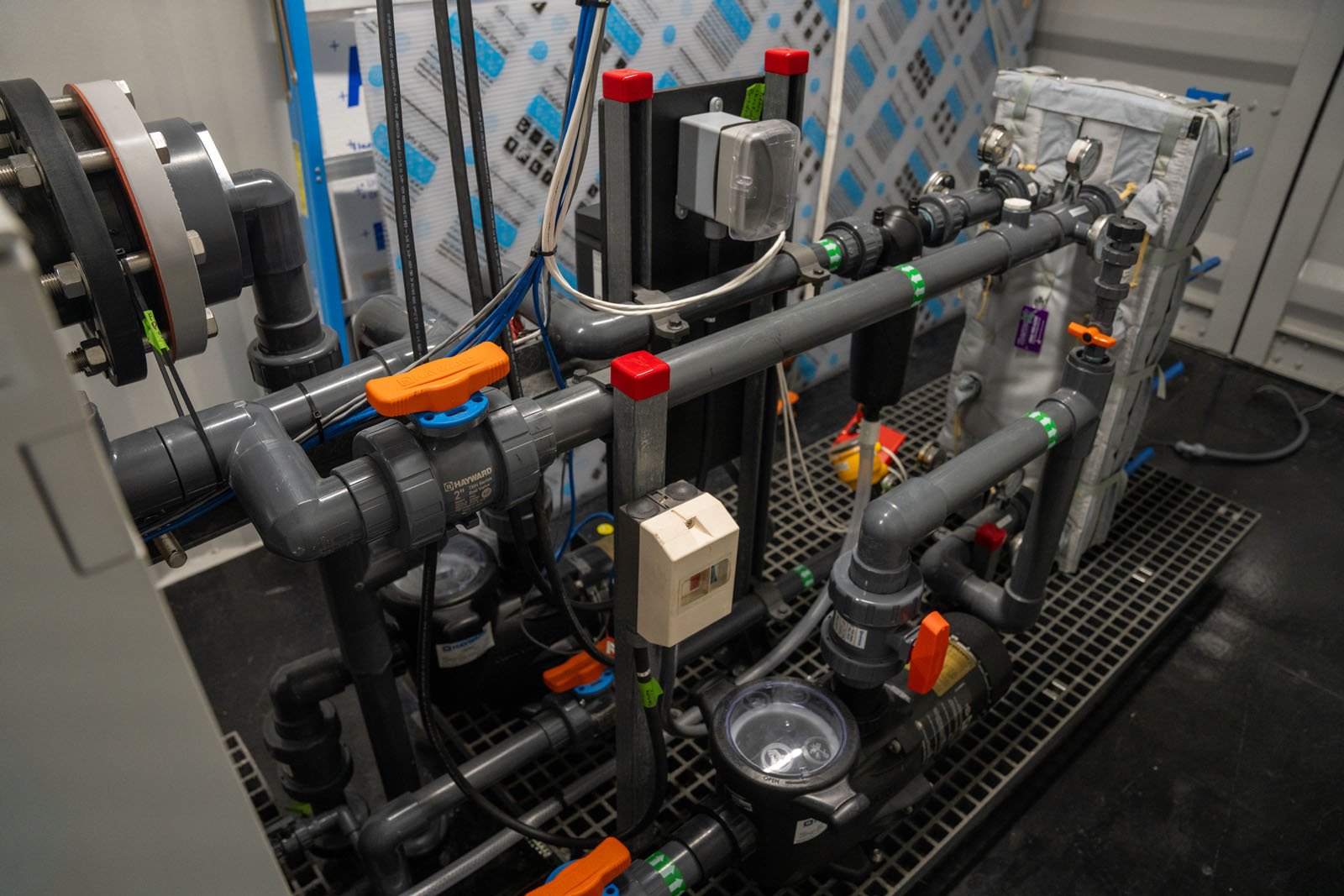

Primary pumps, controls, and filtration components are pre-fabricated onto FRP skids.

-

![]()

Equiment skids are stored for final installation until container modifications are complete.

-

![]()

Raceway manifolds and other plumbing components are pre-fabricated at CEE to accelerate installation and commissioning on site.

-

![]()

Raceway manifolds assembled, completed, and ready for shipment inside Life Support System containers.

-

![]()

Installation and preliminary testing of the SCADA.

-

![]()

Wiring the SCADA to programmable logic controllers on the equipment skids.

-

![]()

Finalize plumbing, wiring, and installation of the Heat Exchanger skids.

-

![]()

Field testing Heat Exchanger performance and all components of Life Support Systems in a closed recirculation loop.

-

![]()

CEE perfoms extensive testing of all systems components before Life Support System containers are prepared for shipment.

-

![]()

Equipment and materials payload is packed and secured for survey and inspection by a licenced Marine Surveyor prior to container loading and transport to the Port.

-

![]()

Loading for transport to the Shipping Port.

-

![]()

Life Support Systems containers arrive and are placed on site. Raceways arrive via separate freight and prepared for installation.

-

![]()

Materials and premanufactured components are unpacked and organized onto a staging area.

-

![]()

Raceway leg supports are cut and installed.

-

![]()

Raceways are prepared drilling and installation of bulkheads and circulation manifolds.

-

![]()

Installation of raceway manifolds, circulation pumps, drains, and secondary shade/rain covers.

-

![]()

Site is surveyed, marked, and ready for aligning raceways into position for plumbing and wiring service outlets.

-

![]()

Trenches excavated for underground piping runs.

-

![]()

Raceway supply and drain plumbing installed and connected to Life Support System container and site discharge well.

-

![]()

Arrival of second Life Support System container.

-

![]()

Drains and closed-loop recirculation pumps are plumbed.

-

![]()

Main power and comms connected to SCADA and all systems components.

-

![]()

Isolated testing of individual system components.

-

![]()

System is filled with seawater as final probes and sensors are installed.

-

![]()

SCADA components individually tested and validated.

-

![]()

SCADA User-Interface.

-

![]()

SCADA commissioned into full operation. CEE performs two weeks of intensive programming and testing of systems components, alarms, data collection, logic control, automation and redundancy to verify fail-safe operation under any scenario.

-

![]()

Arizona State University’s Ridge to Reef Restoration Center.

Commissioned 2024

-